Stainless Screw Barrel for Food Processing Extrusion

| Unit Price: | 100~100000 USD |

|---|---|

| Min. Order: | 1 Set/Sets |

| Packaging: | Wooden case or others |

|---|---|

| Productivity: | 300,000-500,000 sets per year |

| Brand: | Jinyi |

| Transportation: | Ocean,Land,Air,Express,By Trian |

| Place of Origin: | Zhejiang, China |

| Supply Ability: | 2500 sets per month |

| Certificate: | ISO 9001:2015 |

| HS Code: | 8477900000 |

| Port: | Ningbo,Shanghai,Hangzhou |

Basic Info

Model No.: Food processing

Click on the follow link to find out more information: https://www.jinyi-machinery.com/food-processing-screw-barrel/

Company Info

- Company Name: Ningbo Jinyi Precision Machinery Co., Ltd.

- Representative: ZHANG LIBO

- Product/Service: Injection Screws , Injection Barrels , Extrusion Screws , Extrusion Barrels , Tie Bars , Twin Screw Barrels

- Capital (Million US $): 30 millions

- Year Established: 2003

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 21% - 30%

- Total Annual Purchase Volume (Million US $): US$10 Million - US$50 Million

- No. of Production Lines: 12

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 21 -30 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): Above 100,000 square meters

- Factory Location: 158 Qiancheng Rd, Zhenhai District

- Contact Person: Ms. Melody

- Tel: +86-574-55002386

Premium Related Products

Other Products

Hot Products

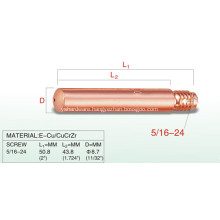

Hrsbme235 MIG Welding Gun for Brazil MarketHrmb23kd MIG Welding Gun for Europe MarketWp 24G TIG Welding Torch BodyHrabi 150, 200, 250 Swan Neck for Hrbinzel Welding TorchHrmb Liner 0.6-1.6mm Compatible for Hrbinzel Welding Torch LinerHrabi150, 200 Welding Gas Nozzle for Hrbinzel MIG Welding GunHrabi 150, 200, 300, 450 Compatible for Binzel Tip HolderHrbinzel Welding Torch Contact Tip (M5X18)Wp-9 Air-Cooled TIG Welding GunHrbinzel36kd Gas Cooled Welding Gun for SolderingCNC Precision MachiningPrecision Auto PartsBrass UnionAir Hose Brass Fitting ProductsYshock-3007Contact TipSand Casting Water Pump Parts