What is the difference between cold welding machine and argon arc welding machine

2021-07-11

Comparison of the welding effect between the triple cold Welding Machine and the argon arc welding machine:

What is the difference between the triple cold welding machine and the argon arc welding machine:

1. Difference in welding temperature: The welding temperature is lower than two-thirds of the argon arc welding machine. The welding time of the three-phase imitation laser cold welding machine is precisely controlled. That is, the maximum current of the welding machine is used for welding. The base material after welding is used. The temperature is only tens of degrees, and it can be touched by hand.

2. The difference in the amount of deformation: thin plate welding is not easy to deform, precisely because the welding time of the triple cold welding machine is precisely controlled, the welding temperature is much lower than the argon arc welding machine, so the triple cold welding machine is more in the thin plate welding than the argon arc welding. The machine has a great advantage, the thin plate welding deformation is very small, hand-welding the thinnest can reach 0.2mm plate.

3. The difference in the brightness of the weld bead: The weld bead of the Sanhe cold welder is bright and white, and the weld bead will not be black after the weld as the argon arc welder.

4. The difference in the function of the welding machine: Sanhe cold welding machine has a variety of welding modes, including: precision spot welding, precision continuous spot welding (imitation laser welding), argon arc welding, pulsed argon arc welding (in the high-grade argon arc welding machine Only has), it can be said that the triple cold welding machine can be used in one machine, it can be used for cold welding, can be used as an argon arc welding machine, and can also be used with automatic welding.

5. Differences in welding effects: After the welding of Sanhe cold welding machine, the welding spot is smooth and white, and the welding treatment is simple and convenient. It can be comparable to the welding effect of high-grade laser machines, and it will not be like the argon arc welding machine. Severe darkening, hard to polish and so on.

Welding Robot are currently being widely used in the areas of defense, shipbuilding, marine technology, chemical equipment production, pressurized vessel manufacturing and nuclear power installations.

We design our products to meet the specifications of process flow, while taking into consideration the restrictions of cutting and welding. Our products are equipped to solve the numerous problems which arise in equipment fabrication, such as making accommodations for nonstandard work piece sizes and incorrect locations.

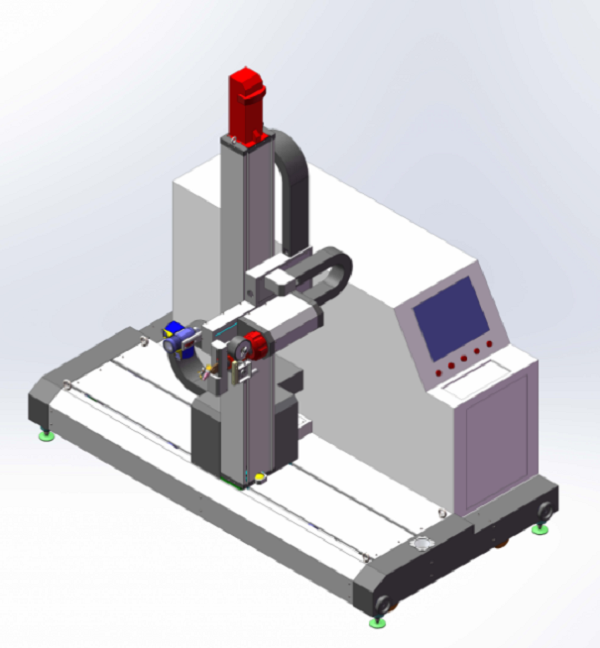

Automatic Tube-Plate Welding Robot

Scope of application

This robot is mainly designed for the welding of tube and plate on the shell and tube heat exchanger. It applies advanced vision positioning, laser vision tracking and intelligent control technologies to achieve real automatic tube-plate welding without manual operations.

Product features

• Automatic positioning and changing position: it applies advanced vision feedback technology to achieve non-contact positioning, which can avoid manual shift, insertion and extraction in mechanical positioning process. It makes the positioning process more quick and accurate.

• Laser vision measurement: it extracts the three dimensional information of the welding position automatically using laser vision system, which solves the problems caused by non-standard shape and wall thickness of the tube, and positioning error between the welding gun and the workpiece in the real production process.

• It can weld many kinds of workpieces, including steel bar, waist-shaped tube, oblate tube and some other non-circular workpieces.

•The welding head uses conventional high quality wire feeder, motion electromechanical components, which are more reliable and durable.

•Intelligent digital AC servo control system runs automatically. The operation process is easy, which can lower labour intensity and skill requirements.

| Model number | TPWR-5 | ||

| Welding material | Carbon steel, stainless steel, titanium alloy | Protective gas | Argon |

| Tube diameter | φ8~φ80 mm(customizable) | Cooling mode of the welding gun |

Water-cooling

|

| Tube position | Out of, parallel, inside of the plate | Welding gun obliquity | 0~30 degrees (adjustable) |

| Movement stroke(mm) | 1500(w) ×1800(h) ×280(z) | Welding speed | ≤12 rpm |

| Welding wire diameter | φ0.8.φ1.0mm | Equipment size(mm) | 2550×2800×1760 |

| Tungsten diameter | φ2.4~φ3.2mm | Equipment weight | 900kg |

| Welder rated current | 300A | ||

Welding Robot, Welding Machine, Head Of Welding Robot, Curved Plate Bevel Cutting Robot

Ningbo Yongshock Precision Machinery Company LTD. http://www.longxuanmachines.com